Critical Chain Project Management (CCPM) Explained

Why are projects often delayed? Why do some of them never succeed? Is it even possible for a project to be completed on time and within budget while still delivering what the client asked for? Many have attempted to answer over these questions over the years, leading to the development of several project management methodologies. Among these, CCPM stands out as a relatively modern method that challenges these other traditional project management methods and philosophies.

CCPM stands for ‘Critical Chain Chain Project Management’ and originates from the Theory of Constraints (TOC). This article serves as an introduction to CCPM where we discuss:

- Introduction to Critical Chain Project Management (CCPM)

- Core Principles of Critical Chain Project Management (CCPM)

- Benefits of Critical Chain Project Project Management (CCPM)

- Conclusion

By the end of this article, readers will be equipped with a thorough understanding of CCPM, empowered to evaluate its suitability for their project environments, and inspired to adopt and adapt its principles to enhance their project management practices. In case of more questions, feel free to reach out to us on LinkedIn or at support@a-dato.com.

📈🔗 What is CCPM?

CCPM is a method of planning and managing projects that emphasizes the resources (people, equipment, space, etc.) in addition to the task sequence required to execute a project. At the heart of CCPM is the identification and management of the project’s critical chain—a concept that extends beyond the traditional critical path to incorporate resource constraints and their impact on project timelines (Leach, 1999). By redefining task durations, eliminating padded estimates, and introducing strategic buffers, CCPM shifts the focus from individual task completion to the overall progress of the project. This approach not only enhances project efficiency but also fosters a collaborative project environment by aligning team members toward a common goal.

Critical Chain Project Management (CCPM) was first introduced in 1990 at the International Jonah Conference (Ghaffari & Emsley, 2015). Here, Mr. Eliyahu Goldratt, the author of ‘The Goal’ which introduced the Theory of Constraints (TOC), first mentioned CCPM as a novel approach to managing projects. While this conference provided a taste of what was to come, it was only the beginning for CCPM. In 1997, Mr. Goldratt decided to replicate the success of ‘The Goal’ with a new book that would focus on applying the principle of TOC to project management. The result was a new book called ‘Critical Chain’ and the birth of Critical Chain Project Management. In the following section, we will go over the key features of CCPM.

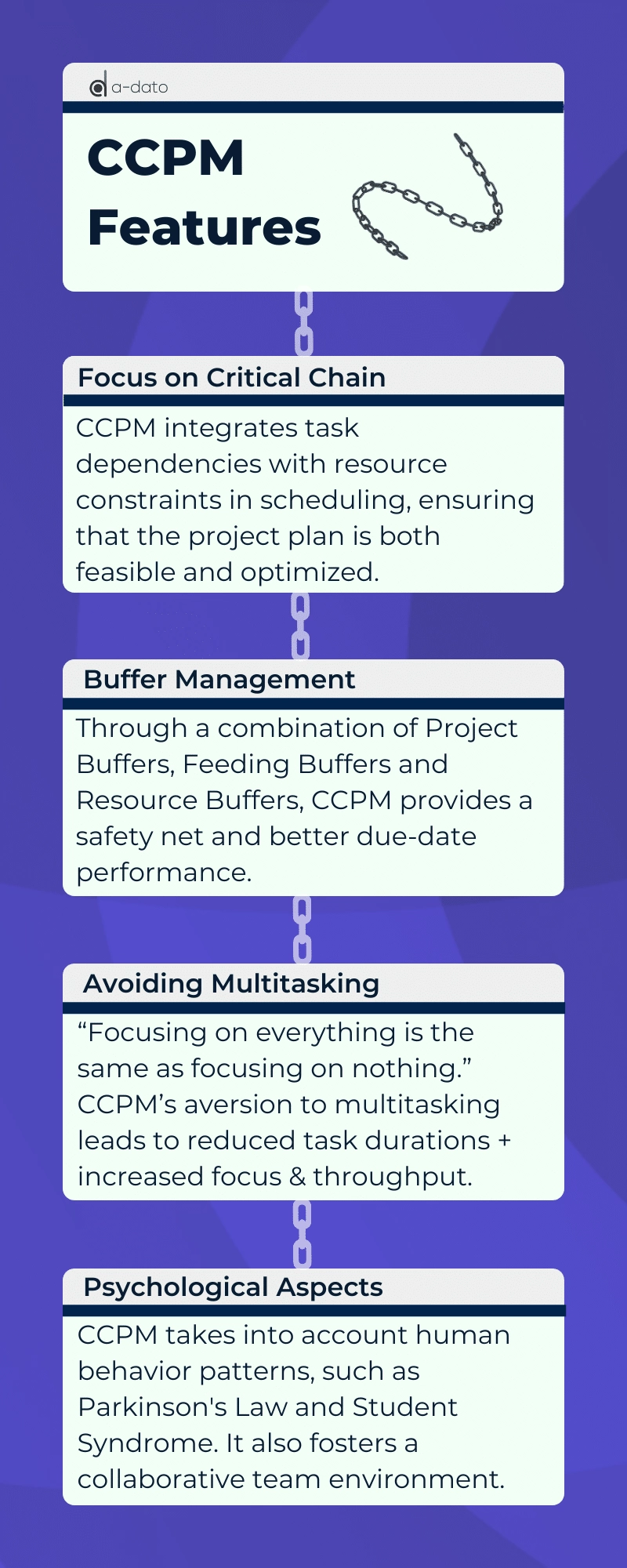

✨🔑 Core Features of CCPM

Several core features set CCPM apart from other methodologies. Many of these features find their roots in TOC, with a focus on improving project delivery times, resource utilization, and overall project success rates.

Focus on Critical Chain

The critical chain concept is essentially an extension of the critical path concept. But what is Critical Path? The Critical Path can be defined as the “longest path of dependent tasks (determined by the days of estimated effort)” (Kendall, 2020). Thereby, only task dependencies were considered when preparing the project schedule, not resource dependencies. A resource dependency takes place when a resource is required in multiple parts of the project simultaneously. So, what is the Critical Chain in project management? It is defined as the longest chain of dependent events, considering task dependencies as well as resource dependencies.

Buffer Management in CCPM

Project Buffers

A central feature of CCPM is the usage of project buffers (Altarazi & Bao, 2015). A project buffer is a safety margin to protect the project from variability in task duration. Further, CCPM aggregates these margins into a consolidated project buffer at the end of the critical chain instead of them to individual tasks. The purpose of this buffer is to absorb any such variability and ensure greater due-date performance.

While Goldratt suggested that this project buffer needs to be 50% of the overall safety time on the project critical chain, the project buffer size can be calculated in different ways for different kinds of projects.

Feeding Buffers

In addition to project buffers added at the end of a project, CCPM also utilizes ‘Feeding Buffers’. These Feeding Buffers are added at points where non-critical chains (sequences of tasks not on the critical chain) feed into the critical chain (Hu et al., 2016). Feeding buffers protect the critical chain from delays in these non-critical tasks, ensuring that any variability does not impact the project’s overall timeline.

Resource Buffers

In addition to project buffers and feeding buffers, CCPM also makes use of resource buffers. Resource buffers are alerts or mechanisms to ensure that critical resources are available exactly when needed (Hu et al., 2016). They act as early warning systems to prevent resource-related delays on the critical chain.

🚫🤹♂️➡️🧘 Elimination of Multitasking

Goldratt once famously said, “Focusing on everything is synonymous with not focusing on anything”. The philosophies behind CCPM and TOC are inherently against multitasking and reducing Work-in-Progress (WIP), resulting in several advantages.

Reduced Task Durations

CCPM encourages more realistic task durations by eliminating safety margins from individual tasks and aggregating them into buffers (Altarazi & Bao, 2015). This, coupled with the focused approach of working on one task at a time, significantly reduces the need for multitasking, a common source of inefficiency and delays in projects.

Increased Focus and Throughput

With less multitasking, resources can focus more intensely on the task at hand, leading to faster task completion and higher-quality outcomes. This focused approach enhances overall throughput and efficiency in project execution.

🔗👥⚙️ Task Dependency and Resource Scheduling

Integrated Task and Resource Scheduling

CCPM integrates task dependencies with resource constraints in scheduling, ensuring that the project plan is both feasible and optimized. This holistic view prevents overcommitment of resources and ensures that critical resources are prioritized for tasks on the critical chain.

Dynamic Adjustment

CCPM allows for dynamic adjustments to the project plan, accommodating changes in resource availability and task durations. This flexibility ensures that the project remains on track despite the inevitable changes that occur during execution.

🧠💡 Emphasis on Psychological Aspects

Addressing Human Behavior

CCPM takes into account human behavior patterns, such as Parkinson’s Law (work expands to fill the time available for its completion) and Student Syndrome (the tendency to start tasks just before their deadlines). By removing safety margins from individual tasks and placing them in strategic buffers, CCPM encourages timely task initiation and completion.

Promoting Team Collaboration

The methodology fosters a collaborative team environment by aligning all members toward the common goal of project completion. This collective focus helps in overcoming individual and departmental silos, enhancing overall project performance.

📊🚀 Benefits of CCPM

Enhanced Project Completion Rates

A primary benefit of CCPM is its positive impact on project completion rates. According to Leach (2005), “CCPM leads to a higher percentage of projects completed on time, which directly translates into increased project throughput for organizations.” This improvement is largely due to the methodology’s focus on the critical chain and the elimination of wasteful multitasking, ensuring that resources are optimally utilized and project milestones are met more reliably.

Improved Resource Efficiency

CCPM promotes more efficient use of resources by addressing the common pitfalls of multitasking and task padding. Newbold (1998) emphasizes that “by reducing the inefficiencies associated with multitasking and providing clear priorities through the critical chain, resources can be more effectively allocated to the tasks that truly matter.” This not only boosts individual productivity but also enhances the overall resource efficiency across the project.

Reduced Project Duration

The strategic use of buffers and the elimination of inflated task durations contribute to a significant reduction in overall project timelines. “Projects under CCPM are often completed in less time compared to those managed under traditional methodologies,” states Goldratt (1997), highlighting the efficiency of CCPM in accelerating project delivery.

Increased Flexibility and Adaptability

CCPM’s dynamic nature allows for greater flexibility and adaptability in project management. By continuously monitoring buffer consumption, project managers can make informed decisions and adjustments, ensuring that the project remains on track despite unforeseen challenges. This adaptability is crucial in today’s fast-paced and ever-changing project environments.

Want to see these benefits in action? Check out a CCPM Case study here!

🔚🎉 Conclusion

As Leach (1999) poignantly notes, “The adoption of CCPM can be a catalyst for change, driving organizations towards more efficient and effective project management practices.” However, it’s important to recognize that the successful implementation of CCPM requires a shift in organizational mindset, with a focus on collaboration, continuous improvement, and a willingness to embrace new methodologies.

Ultimately, the adoption of Critical Chain Project Management offers the promise of more predictable project outcomes, optimized resource allocation, and the ability to deliver projects within the constraints of time and budget. As project management continues to evolve, CCPM stands out as a methodology that not only challenges conventional wisdom but also offers a practical path to enhanced project success.

Want to learn about the LYNX Software by A-dato uses CCPM? Click here.

Want to see it in action? Book a free demo with us!

References

- Altarazi, F., & Bao, H. (2015). Investigating the impact of buffer size in critical chain management. Flexible Automation and Intelligent Manufacturing (FAIM2015), 1-8.

- Goldratt, E. M. (1997). Critical Chain. Great Barrington, MA: The North River Press.

- Ghaffari, M., & Emsley, M. (2015). Current status and future potential of the research on Critical Chain Project Management. Surveys in Operations Research and Management Science, 20(2), 43–54. https://doi.org/10.1016/j.sorms.2015.10.001

- Hu, X., Demeulemeester, E., Cui, N., Wang, J., & Tian, W. (2016). Improved critical chain buffer management framework considering resource costs and schedule stability. Flexible Services and Manufacturing Journal, 29(2), 159–183. https://doi.org/10.1007/s10696-016-9241-y

- Kendall, G. (2020). Critical chain and critical path – what’s the difference? tocinternational.com. https://exepron.com/wp-content/uploads/2021/12/Critical-Chain-and-Critical-Path-What-s-the-Difference-By-Gerald-I.-Kendall-.pdf

- Leach, L. P. (1999). Critical chain project management improves project performance. Project Management Journal, 30(2), 39–51. https://doi.org/10.1177/875697289903000207

- Newbold, R. C. (1998). Project Management in the Fast Lane: Applying the Theory of Constraints. St. Lucie Press.